Nanoracks Bishop Airlock

The Nanoracks Bishop Airlock being manufactured in the Space Station Processing Facility (SSPF). | |

| Module statistics | |

|---|---|

| Launch date | 6 December 2020, 16:17:08 UTC |

| Launch vehicle | Falcon 9 Block 5 (Booster B1058.4) |

| Docked | Tranquility module port |

| Mass | 1,059 kg (2,335 lb) [1][2] |

| Height | 1.80 m (5 ft 11 in) |

| Diameter | 2.014 m (6 ft 7.3 in) |

| Pressurised volume | 3.99 m3 (141 cu ft) |

| Configuration | |

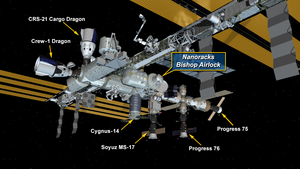

Location of the Nanoracks Airlock Module | |

The Nanoracks Bishop Airlock is a commercially funded airlock module launched to the International Space Station on SpaceX CRS-21 on 6 December 2020.[3][4] It was berthed to the Tranquility module on 19 December 2020 by the Canadarm2.[5] The module was built by Nanoracks, Thales Alenia Space, and Boeing.[6] It is used to deploy CubeSats, small satellites, and other external payloads for NASA, Center for the Advancement of Science in Space (CASIS), and other commercial and governmental customers.[7] NASA plans on using the airlock as a brand new way to dispose large pieces of trash.[8] The name refers to the bishop chess piece, which moves diagonally.[9]

Background

[edit]Under the International Space Station's designation as a facility of the Center for the Advancement of Science in Space, Nanoracks has an agreement with NASA to send payloads from academic and private sources for installation on the ISS' experiment racks or deployment from the equipment airlock in the Japanese Kibō module. Limitations on NASA's use of the JAXA facility created a bottleneck, prompting Nanoracks to develop their own airlock to increase satellite deployment capabilities.[10] NASA also uses the Bishop Airlock to dispose of trash.[11] Astronauts and cosmonauts simply dump their trash via the airlock and the trash is thrown out and burned up in the atmosphere of Earth. This helps out the chronic problem of having to keep trash inside all of the modules for months at a time while waiting for a cargo spacecraft to dump the trash.[8]

A Space Act Agreement between NASA and Nanoracks to develop a private airlock was signed in May 2016,[6] and the Nanoracks–Boeing plan to build and launch the module by 2019 was approved in February 2017.[7] Originally manifested to launch on SpaceX CRS-19 in late 2019,[12] the module was later re-manifested to launch on SpaceX CRS-21.[3]

Manufacturing

[edit]The Bishop Airlock was primarily manufactured by Nanoracks, with parts of the titanium and aluminium pressure shell made by Thales Alenia Space at their factory in Turin, Italy. Boeing manufactured the stainless steel exterior panels and Common Berthing Mechanism (CBM).[13][2] The partly made components were shipped to Kennedy's Space Station Processing Facility for completion, assembly and testing.

Airlock

[edit]The airlock is a four-cubic meter bell-shaped canister that attaches to the Tranquility module.[1] It does not have hatches, instead the Canadarm2 connects to either of the two grapple fixtures in order to move the airlock on or off the station's berthing port which does have a hatch.

The second grapple fixture allows the airlock and its contents to be carried along the main truss on the Mobile Base System.

Airlock operations at ISS

[edit]Typical Airlock Sortie for satellite deployment:[1]

- Payload satellite and deployer loaded into Airlock – Crew

- SSRMS grapple of Airlock – Ground

- Transfer of Airlock power from Node 3 to SSRMS - Ground

- Airlock power and data cables, IMV, and EWC coax cable disconnect – Crew

- Install CBM Controller Panel Assemblies - Crew

- Hatch closure and Air Save Pump hookup to hatch Equalization Valve – Crew

- Air Save Pump depress – Ground

- Vestibule residual air depress – Ground

- CBM bolt disengage – Ground

- SSRMS maneuver to deploy position – Ground

- Satellite deployment – Ground

- SSRMS maneuver back to Node 3 Port and berth Airlock (without CBCS) – Ground

- Air Save Pump repress and leak check – Ground

- Open Hatch – Crew

- Relocate CBM Controller Panel Assemblies - Crew

- Reconnect power and data cables, IMV, and EWC coax cable to Airlock – Crew

- Transfer of Airlock power from SSRMS to Node 3 - Ground

- SSRMS ungrapple - Ground

- Remove payload deployer hardware left behind and stow - Crew

References

[edit]- ^ a b c "Nanoracks Airlock Overview". 1 September 2016. Retrieved 7 December 2020.

- ^ a b "Bishop Airlock". Nanoracks. 1 October 2016. Retrieved 7 December 2020.

- ^ a b "Thales Alenia Space reaches key milestone for Nanoracks ' airlock module" (Press release). Thales Alenia Space. 20 March 2019. Retrieved 22 August 2019.

- ^ Clark, Stephen (2 August 2019). "SpaceX to begin flights under new cargo resupply contract next year". Spaceflight Now. Retrieved 22 August 2019.

- ^ "New Airlock Attached to the Space Station". www.youtube.com. Retrieved 23 December 2020.

- ^ a b "Nanoracks, Boeing to Build First Commercial ISS Airlock Module" (Press release). Nanoracks. 6 February 2017. Retrieved 22 August 2019.

- ^ a b Garcia, Mark (6 February 2017). "Progress Underway for First Commercial Airlock on Space Station". NASA. Retrieved 22 August 2019.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ^ a b "A New Doorway to Space". NASA. 16 November 2020. Retrieved 23 December 2020.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ^ Leinfelder, Andrea (28 August 2019). "Nanoracks, commercial space industry march ahead with space station airlock". Houston Chronicle. Retrieved 7 December 2020.

- ^ Berger, Eric (27 January 2016). "To boost commercial activity, NASA may add private airlock to ISS". Ars Technica. Retrieved 22 August 2019.

- ^ Kooser, Amanda (7 July 2022). "See the International Space Station Toss a Bag of Trash Out of an Air Lock for the First Time". CNET. Retrieved 19 July 2022.

- ^ "Nanoracks Commercial Space Station Airlock "Bishop" Completes Critical Design Review, Moves to Fabrication" (Press release). Nanoracks. 17 April 2018. Retrieved 22 August 2019.

- ^ Krebs, Gunter (30 September 2016). "Bishop". Gunter's Space Page. Retrieved 7 December 2020.